Automated Leak Detection

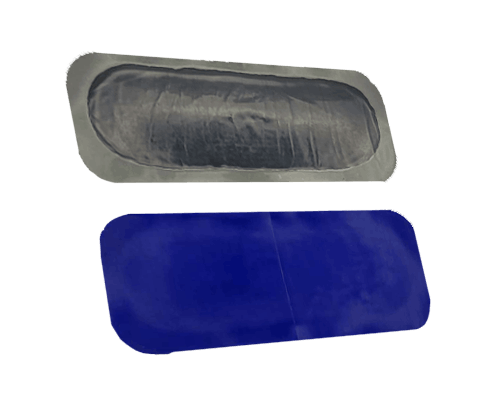

Let us help you stop leaking vehicles from slipping through the inspection process. Our wireless sensors provide a SMART manufacturing solution. Low-cost, low-profile sensors are placed directly on the vehicle chassis before the trim and carpeting are installed. After the vehicle moves through a high-pressure wash line, the sensors detect any water inside the vehicle. Dry vehicles move on for shipment, while the leaking vehicles are sent back for rework.