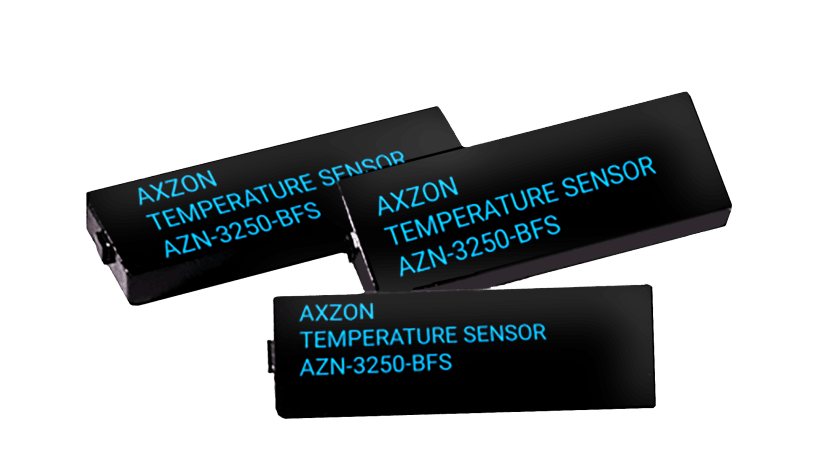

AZN3240 Long-Range Rugged Wireless Temperature Sensor

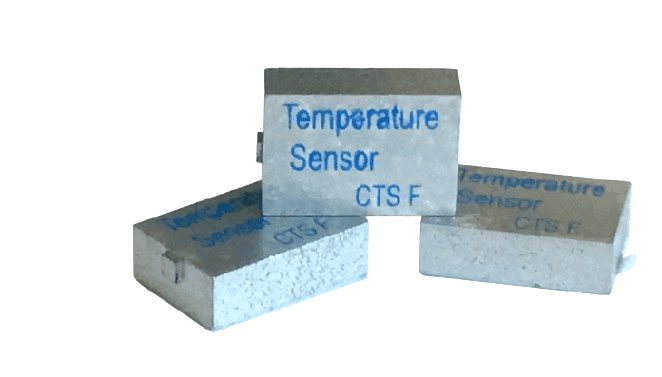

The AZN3240 is a wireless battery-free temperature sensor. This rugged sensor monitors electric distribution and switching equipment temperatures. Applications include utility-grade electric power distribution, factory and industrial electric service switchgear, and other applications where metal surfaces are common.